Made in Italy

MADE IN ITALY CRAFTSMANSHIP

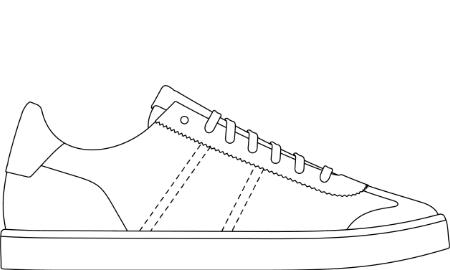

The aim of RUBIROSA is to make shoes ever better and more comfortable. A beautiful shoe is like a three-dimensional, moving sculpture, which requires harmony, elegance, balanced proportions, style and, above all, craftsmanship.

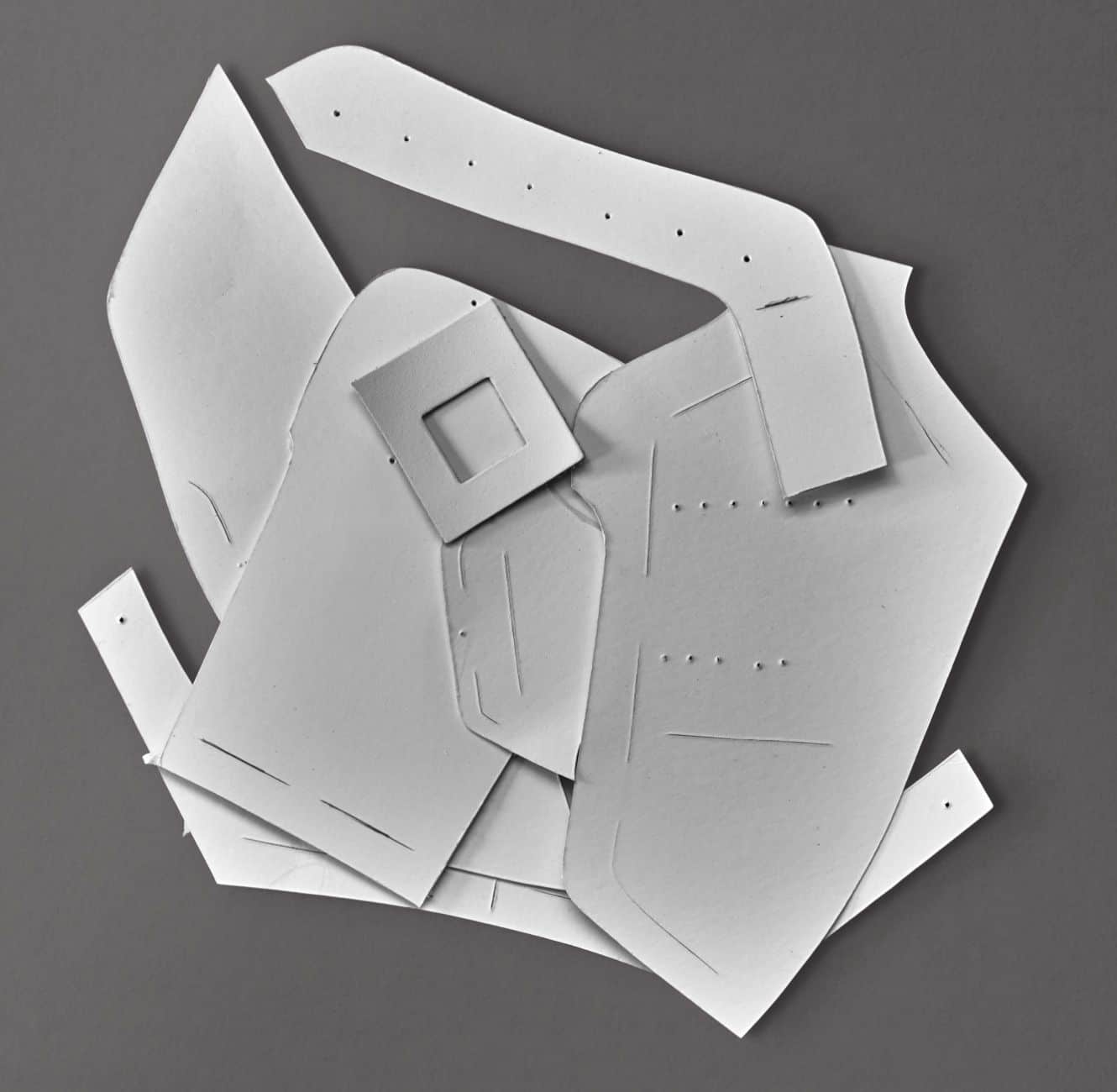

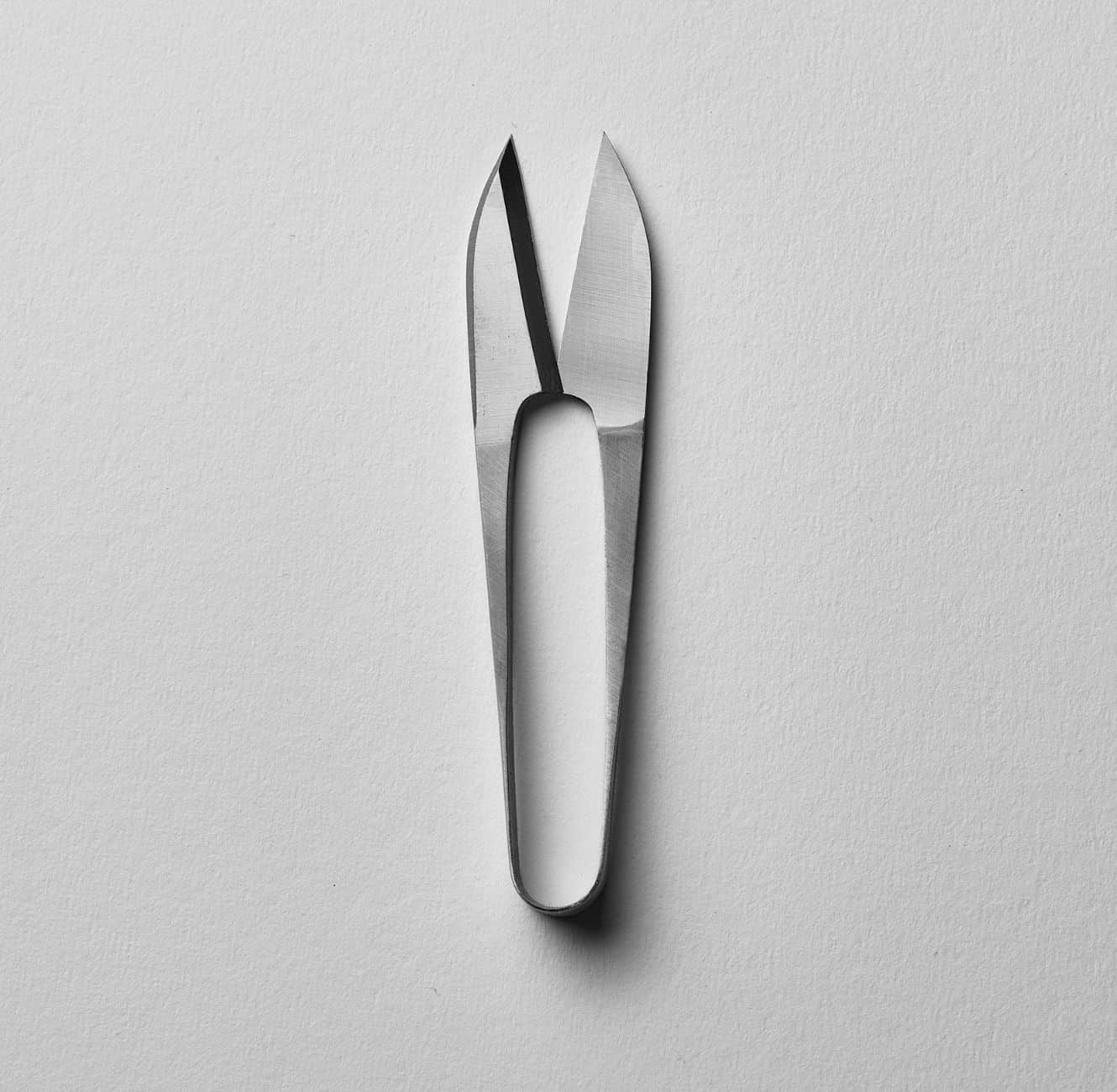

From the selection of the material, the control of quality and colour nuances to the final approval of a shoe, at least 100 operations are necessary. Each pair is individually cut using a template made of cardboard and pulled over the last by hand, and the leather upper is hand-stitched.

Made in Italy

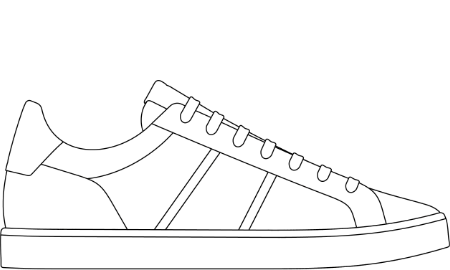

The area around the Riviera del Brenta near Venice is known as one of the oldest shoemaker regions in Italy. Today, crafts workshops and production companies still focus on the art of developing and producing high-quality shoes.

The thing that makes the Riviera del Brenta region special is the fact that almost all “designer” shoes on the global market of shoe factories are produced, largely shaped, and marketed on the Riviera del Brenta.

Only the most experienced craft artists from this region are allowed to lay hands on the RUBIROSA shoes. These include family businesses that are in their third generation of manufacturing the products with great passion and dedication.

Materials

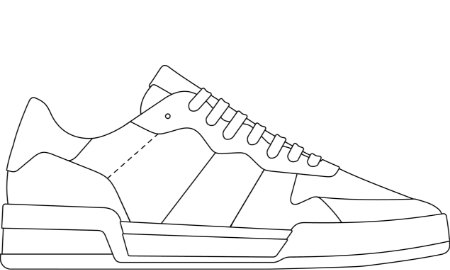

Leather is a fascinating product and has accompanied, protected and kept mankind warm from the outset. Despite the thick, almost waterproof skin, it is breathable. This means that it allows sufficient moisture and air through and absorbs grease like human skin.

As leather is perishable however, man quickly started developing methods to stabilise the raw animal hide and thereby make it more durable. This process is known as tanning.

The leather types used by RUBIROSA are vegetable tanned or chrome tanned. Each of these tanning methods gives the leather specific characteristics, which are significant for its later application.

Chrome tanning creates a soft, light and pliable leather and is therefore used as upper leather.

Vegetable tanning is used for interior leather. As it is purely plant-based and the interior leather might later come into direct contact with the skin, allergic reactions are ruled out with this tanning process.

CLEANING AND CARE

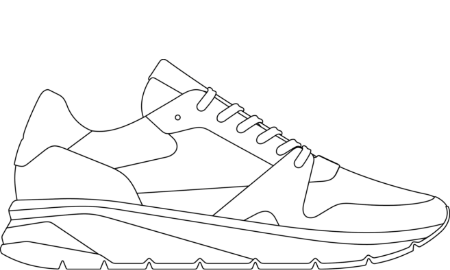

Nappa Calf Leather

Smooth leather shoes should be cleaned with a soft cloth; if stained with coarse dirt, it should be cleaned with a brush.

Occasionally special shoe shampoos or saddle soap can be used as an adjunct for this. They are massaged into the leather with a sponge or cloth and then wiped off. Let the leather dry slowly and gently afterwards.

Even smooth leather shoes should be impregnated from time to time: the right time for this is after cleansing and before the application of creams.

Suede Calf Leather

Suede is dry-cleaned with a fine brush for dust and dirt. We generally recommend using crepe or brass brushes for rough cleaning.

For stubborn stains or salt crusting, you can thoroughly clean suede with water and curd soap. The leather must be completely wet so that no new crusts arise.

After that, stuff the shoes with newsprint paper and dry slowly and gently. It is best to hang them at room temperature so that they can breathe. Finally, they have to be re-roughened with the appropriate brush.

To refresh the color of suede, use of a liquid paint application or special color activators from specialist retailers is recommended. There are also combination products that refresh and impregnate the shoe.